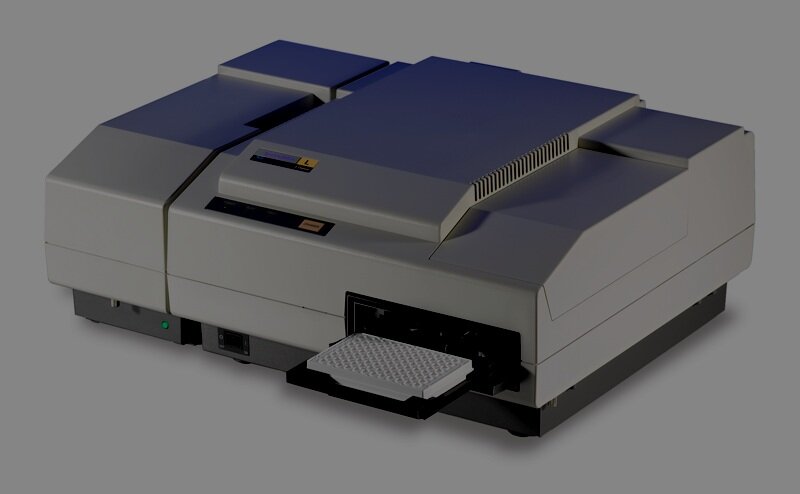

Service for SpectraMax® L Luminescence Microplate Readers

You rely on your equipment. Your equipment should rely on ATG.

Analytical Technologies Group are highly experienced professionals in the maintenance and repair of Molecular Devices microplate instrumentation, including the SpectraMax® L luminescence microplate reader. Our engineers maintain unparalleled knowledge due to our focus on a select few product lines, and our inventory of spare parts kept in stock means that you can get the service you need from ATG quickly and effectively.

See why over 1,000 organizations trust ATG to keep their labs running.

Tips for keeping your SpectraMax® L plate reader in good working order:

Keep your plate reader on a level surface away from vibration. It should not be in direct sunlight, and the environment should not be dusty, drafty, or humid. It should be not be in a location where it may get wet.

The rear of the instrument has multiple vents which cool the unit during operation. Ensure there is at least two inches of space behind the unit for proper ventilation.

Keep the area around the instrument clean and free of dust, especially in the rear since air is drawn in from behind. Dust on the bench quickly becomes dust inside your instrument.

A slip cover can greatly reduce the amount of dust accumulating in the instrument over time; these are highly recommended.

The instrument should be calibrated at least once a year. Calibration can be performed using the internal LEDs, with a custom multi-PMT normalization microplate, or with your own assay materials.

Always keep the plate drawer closed when the instrument is not in use.

Never touch the optic mirrors, lenses, filters, or internal cables. Generally speaking, don’t go poking around inside the instrument. If you do not know what you are doing, you are more likely to break something than fix a problem on your own.

If your instrument configuration has injectors, ensure the bottles are kept clean. Regularly change your solutions.

Periodically verify the dispense accuracy of the injector by running the gravimetric tubing calibration procedure. Replace the injector tips and tubing if performance deteriorates, if you suspect contamination, or when recommended by the software. Perform a calibration any time the injector tubing is replaced.

If the instrument will not be in use for a long period of time, open the stabilizer lids on top of the pumps to relieve compression on the tubing.

If liquid spills in the drawer, power off the instrument and wipe up spills immediately with a lint-free, absorbent material. Allow the unit to air dry completely before powering on.

Having technical problems with your SpectraMax® L?

Fast Response

We provide very prompt responses to customers within one business day.

Fast Turnaround

Our field service engineers are expediently dispatched across North America & Europe to fulfill your service request.

Expert Staff

ATG’s highly trained, highly skilled staff ensure your instruments remain in optimal condition.

Replacement Parts Stocked

To minimize instrument downtime, we stock virtually all parts for the systems in which we specialize.

SpectraMax® L Microplate Luminometer Troubleshooting Tips:

When in doubt, if you get an error message for an unknown reason, turn the instrument off then turn it back on. Sometimes that will clear the issue.

If the computer is failing to communicate with the instrument, ensure all cables are connected properly, then restart both the instrument and the computer.

If the drawer will not open via the drawer button nor the open drawer command in SoftMax Pro, turn the instrument off, wait 5 seconds, turn it back on, then try again. If it still will not open, you will need to perform the manual drawer opening procedure. See the manual for complete instructions. The manual drawer opening procedure is a temporary solution to allow you to retrieve your microplate; it is not for everyday use. Call for service.