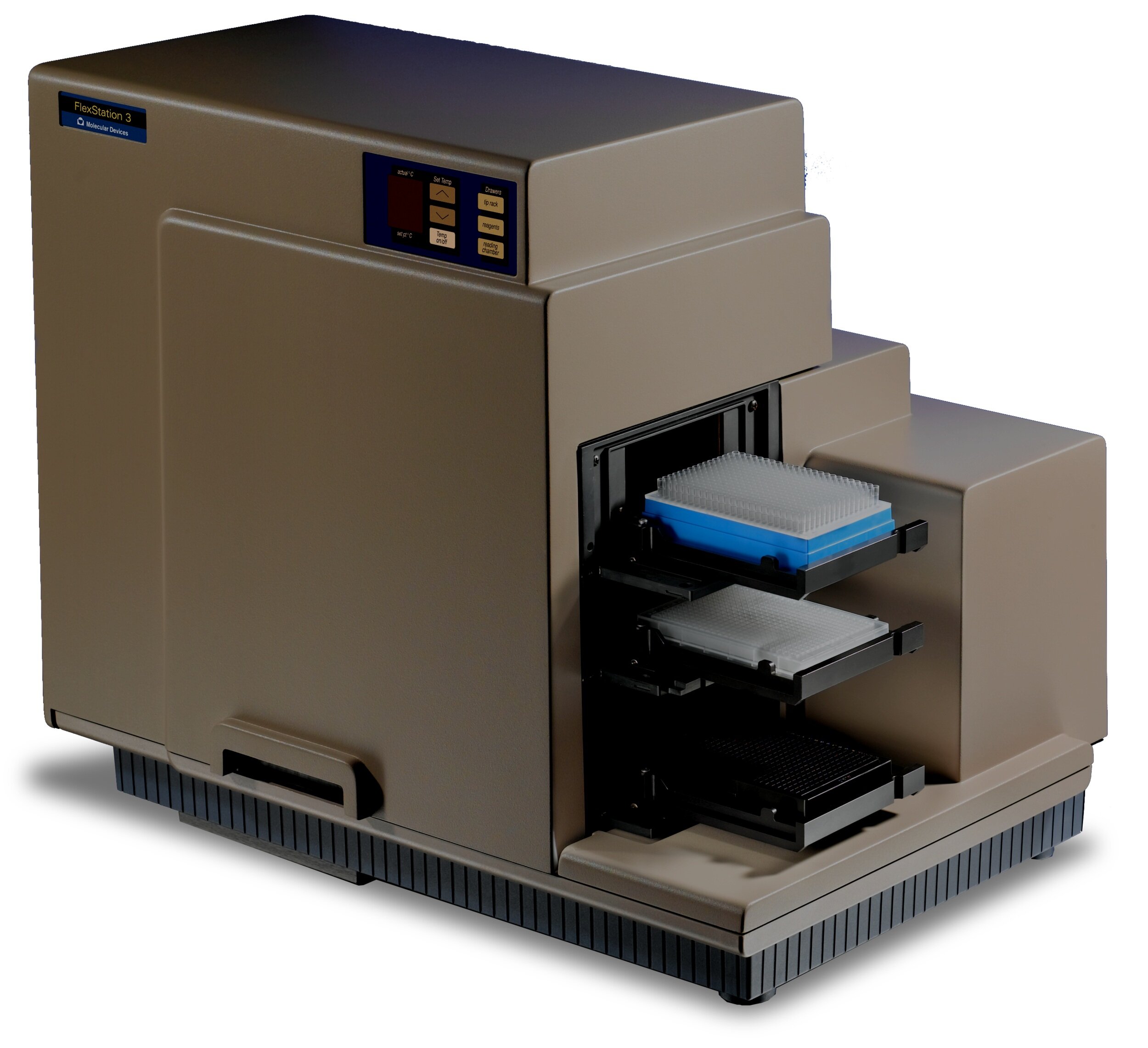

Maintenance & Repair for FlexStation™ Microplate Readers

You rely on your equipment. Your equipment should rely on ATG.

Microplate readers are sensitive instruments which are crucial to many labs’ research. When your microplate reader needs service, you want to ensure that you can obtain it quickly and that the work is performed by knowledgeable engineers who ensure the work is done right the first time.

Analytical Technologies Group has a long history of experience maintaining and repairing Molecular Devices microplate instrumentation, including the FlexStation™ microplate readers. Because we only service a narrow range of instruments, our engineers maintain industry-best knowledge in these lines. Since we maintain stock of replacement parts, we can provide rapid service whether you need routine maintenance or emergency repairs. Our cost-competitive service contracts ensure your equipment delivers the reliable performance you need and expect throughout its life.

Tips for keeping your FlexStation™ series plate in good working order:

The FlexStation™ should be placed on a level surface away from vibration, direct sunlight, dust, drafts, and moisture. You might not think much of it, but these little things can make a difference.

Before performing any maintenance or manipulating the instrument in any way, remove the pipettor tips to prevent damage or spillage.

Do not unscrew anything or attempt to disassemble the instrument in any way not explicitly stated in the manual. You are more likely to break something than fix something if you do not know what you are doing. If your instrument is relatively new, you also may void your warranty by doing so.

You do not need to turn off the power to the instrument when you are done performing runs for the day, however if the instrument will not be used for multiple days (such as over the weekend), it is recommended that you power it off.

Whenever necessary, the outside of the instrument should be cleaned with a cloth or sponge dampened with water, 70% ethanol, or 70% isopropyl alcohol. The reading chamber drawer can be cleaned the same way. Do not attempt to clean the inside of the instrument. Do not spray cleaner directly onto the instrument.

The back of the instrument has vents that prevent it from overheating. Ensure there is at least three inches of space behind the unit for proper ventilation.

Keep the area around the instrument clean and free of dust, especially in the rear to prevent dust being drawn into the instrument through the vents.

Only use tips approved for use with your specific model of FlexStation™

Before each run, make sure that the layout of the tips in SoftMax Pro matches what is in the tip rack and the plates specified in SoftMax Pro correspond to the plates you are using.

Remember to remove the cover of the tip rack before placing it into the carriage.

If you experience a power failure while the instrument is running, turn off the power switch on the back of the instrument and leave it off until electricity is restored.

Having technical problems with your FlexStation™?

Fast Response

We provide very prompt responses to customers within one business day.

Fast Turnaround

Our field service engineers are expediently dispatched across North America & Europe to fulfill your service request.

Expert Staff

ATG’s highly trained, highly skilled staff ensure your instruments remain in optimal condition.

Parts In Stock

To minimize instrument downtime, we stock virtually all parts for the systems in which we specialize.

FlexStation™ Microplate Reader Troubleshooting Tips:

If you get an error message that does not have an obvious resolution or is for an unknown reason, turn the instrument off, wait 5 seconds, then turn it back on. Restart the SoftMax Pro program or the computer which is running it. Sometimes that will clear the issue.

If SoftMax Pro is not detecting the instrument and you just turned it on, it may still be warming up. Wait a minute and check again. If you did not just turn it on, check to ensure that the communication cables are connected and ensure the serial port and serial comm speed settings in the preferences are correct. The issue could also be due to the instrument experiencing a fatal error. Check the FlexStation™ for an error message and restart the instrument.

If the system will not power on, it could be due to a blown fuse. The fuse box is located just to the right of the power switch, between the switch and the power cable connection. Switch the unit off, unplug all cables, open the fuse box, and remove and inspect the fuses. Even if only one fuse is blown, you should replace both fuses. The fuses are 6.3-amp 5 x 20 mm slow blow fuses, which can be purchased from most hardware or electronics stores. A pair of spare fuses are included with the instrument, so if you purchased it new and this is the first time you have blown a fuse, hopefully you still have the replacements on hand.

If liquid spills in the reading chamber drawer while it is outside the instrument, it will drain underneath the instrument. Wipe up any spills immediately.

If you are using spectral scanning and receive an error message regarding missing datapoints, it could be caused by saturation during the scan. Re-scan with the photomultiplier tube (PMT) set to low.

If you are using standard 96- or 384-well microplates and are having difficulties with your readings, did you remember to install the microplate adapter?

If the drawer will not open, you may need to open the drawer manually. Power off the instrument. Using your fingernail or a firm, narrow object inserted about 1/8”, open the drawer to its horizontal position and gently, slowly pull out the carriage. If it does not come out easily, do not force it. The manual drawer opening procedure is a temporary solution to allow you to retrieve your microplate; it is not for everyday use. Call for service if the problem persists.

A pipettor failure could be due to the tip rack cover not being removed, the tip rack being improperly positions, or the tips not being seated properly. These problems can be solved by the user. See the manual for more information.

If the tip rack is jammed and the pipettor head is in the home position, without tips, it could be due to the tips not being seated properly and blocking the drawer movement.

If you experience a mechanical failure which results in liquid remaining in the pipettor tips, or if you receive the error message “Undispensed fluid is in the tips,” you must remove the pipettor head and empty the liquid outside the chamber of the instrument. See the manual for more information.

If you receive the error message “There is no assay plate,” ensure there is a plate in the reading chamber drawer and the plate is correctly seated.

If you receive the error message “Instrument reported a fatal error,” it could be due to tips jamming the read head.

If any errors cannot be resolved, your instrument likely requires service. We can help in a hurry! Contact ATG.